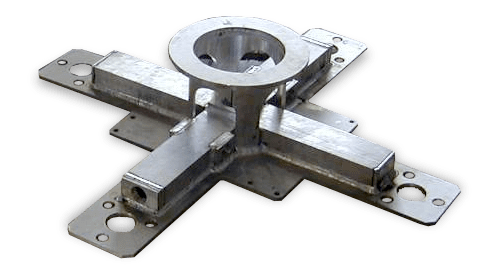

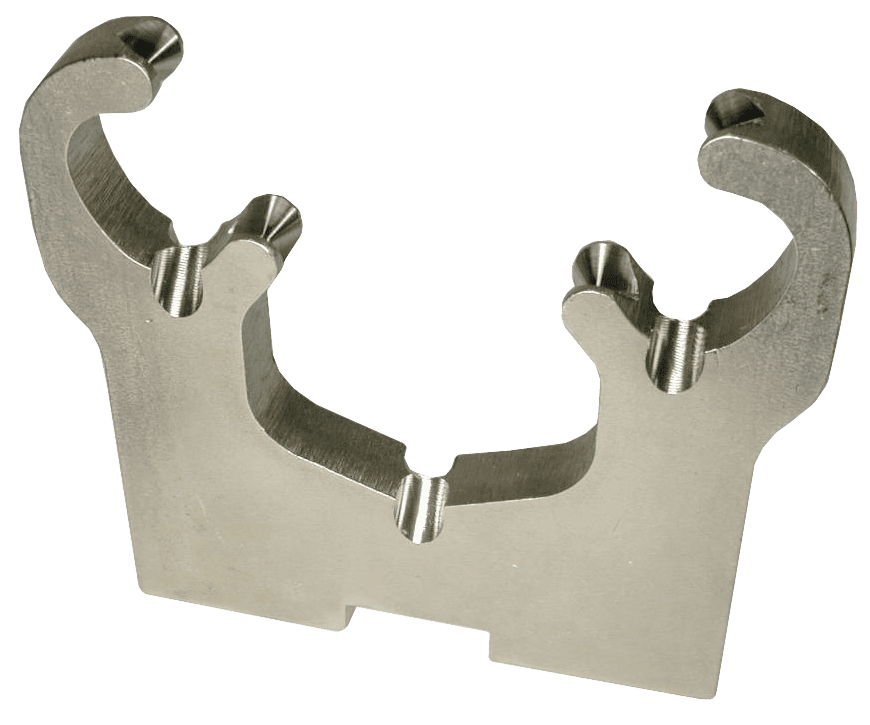

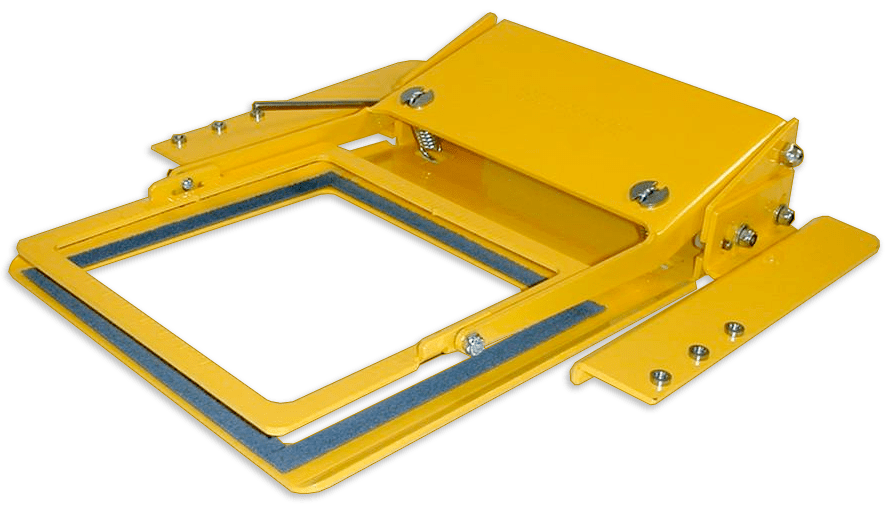

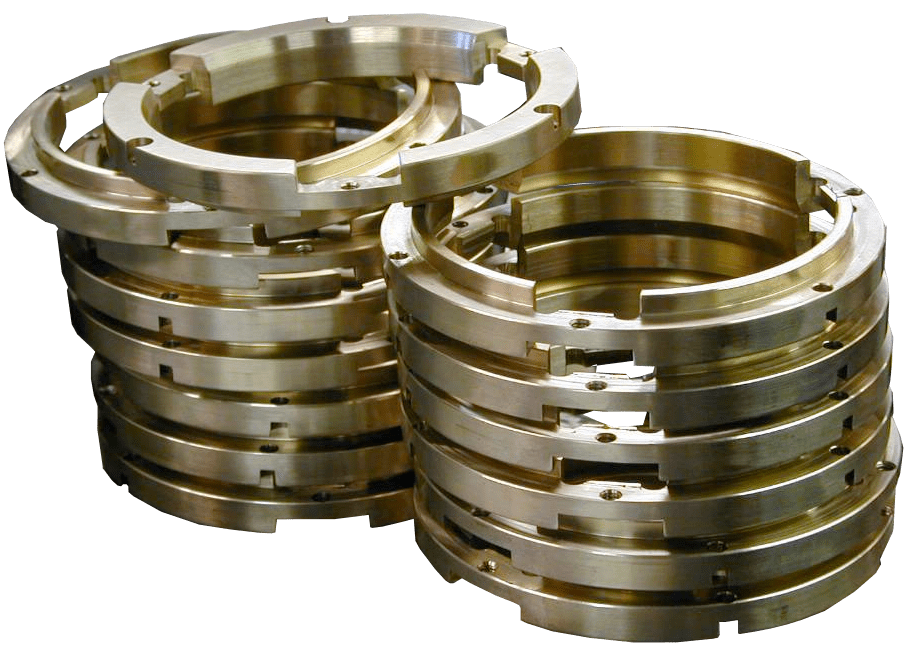

Laser Cut Metal Parts

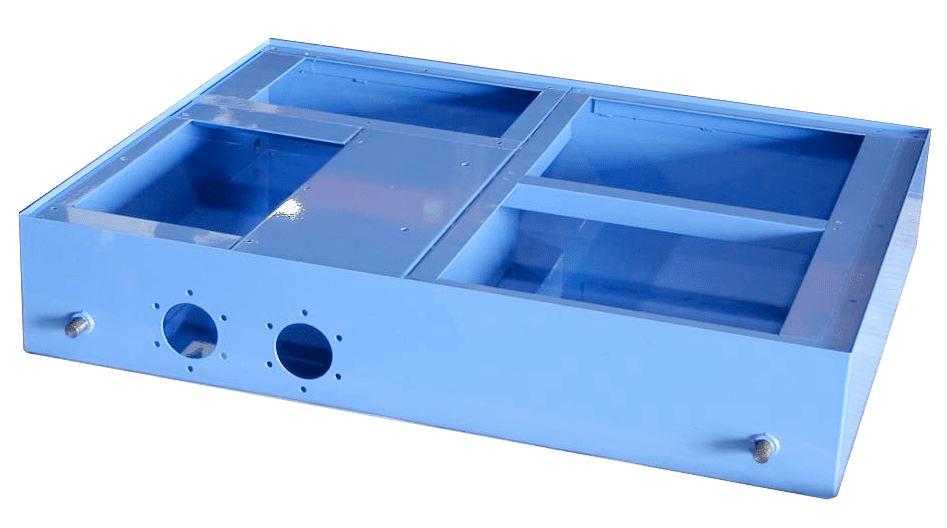

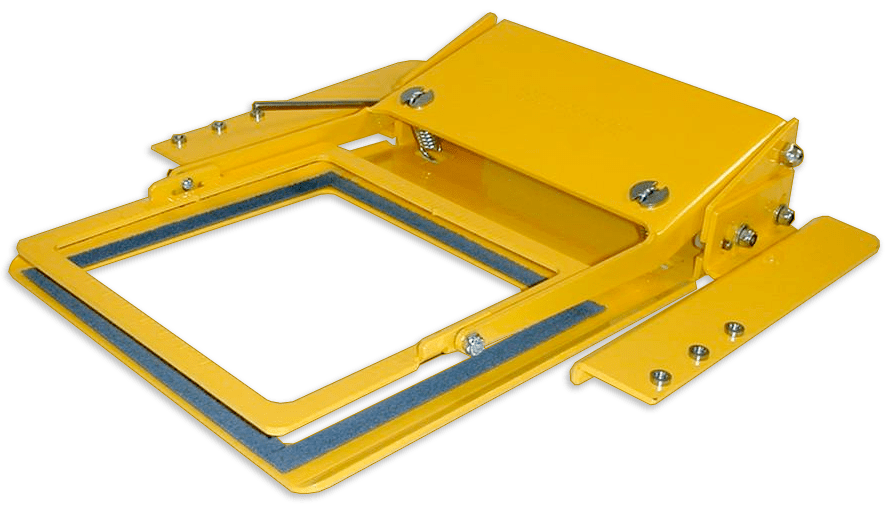

Laser Cutting for Weldments and Fabrications

Laser metal cutting technology allows the engineer to optimize the design of metal fabrications, rather than worrying about the manufacturing constraints of more traditional manufacturing methods. Due to the nature of laser technology, it is safe to say that if the part can be described mathematically, it can be laser cut (within material and machine limitations).

Stainless specialists

Specialists in stainless steel and mild steel parts manufacturing.

One-stop machine shop

Single, reliable source for high-quality parts. Comprehensive in-house capabilities.

Precision parts fabrication

Experienced craftsmanship using advanced technologies.

Fast Lead Times

Quick, accurate parts turn-around through flexible scheduling

Engineering solutions

Partnering to provide the best solution for your part design.

The value of our metal laser cutting services includes both C02 and Fiber Lasers, having both technologies make us more versatile. CO2 lasers work better with thicker materials. Fiber lasers have no moving parts or mirror resulting in faster setup, and works better with thinner materials (3 times faster) and extremely accurate. Fiber lasers cut reflective materials better because your don’t have to worry about back reflections that can damage the machine. The material feed tower on our fiber laser allows us to run unattended hours.

Our large tables allow for the ability to cut larger parts, optimize nests and save time. We use common-line nesting of parts so that neighboring parts have a shared edge whenever possible. And we buy steel in bulk and carry a large inventory for fast delivery of both small runs and production.

Thorough Process and Procedure Documentation

We want to be your manufacturing partner rather than just a parts supplier. To remain competitive in a global market, our customers are looking for partners that offer services above and beyond. All processes and procedures are documented.

Greater Cincinnati location

Batavia, OH 45103

U.S.A.

Give us a call

Contact us by email

Your form submission will be read immediately by Deltec Manufacturing Engineers.